Tse-30 Co-Rotating Twin-Screw Compounding Extruder for Lab

Description

Basic Info

| Type | Plastic Extruder |

| Plastic Processed | PP PE PVC Pet ABS |

| Product Type | Granulating Extruder |

| Feeding Mode | Multiple Feed |

| Assembly Structure | Integral Type Extruder |

| Screw | Twin-Screw |

| Engagement System | Full Intermeshing |

| Screw Channel Structure | Deep Screw |

| Exhaust | Exhaust |

| Automation | Automatic |

| Computerized | Computerized |

| Keyword | Twin Screw Extruder |

| Color | Any Color as You Require |

| Warranty | 1 Year |

| Contactor | Schnerder |

| Output | 750-1250kg/H |

| Motor Power | 110kw, 132kw, 160kw, 200kw |

| Motor | Simens AC |

| Condition | New |

| Place of Origin | Jiangsu, China (Mainland) |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Transport Package | Wood Packing |

| Specification | CE ISO9001 |

| Trademark | kairong |

| Origin | Jiangsu, China (Mainland) |

| HS Code | 84772090 |

| Production Capacity | 500sets/Year |

Product Description

Product Description

1. Plastic pellet machine extruder Parameter

| Model | Diameter | L/D | Screw rotary | Motor Power | Torque | Capacity |

| TSE-40B | 41mm | 32-52 | 600r/min | 30kw | 239 | 90-150kg/h |

| TSE-52B | 51.5mm | 32-56 | 600r/min | 55kw | 438 | 225-300kg/ |

| TSE-65B | 62.4mm | 32-60 | 600r/min | 90kw | 716 | 200-300kg/h |

| TSE-75B | 71mm | 32-64 | 600r/min | 132kw | 1050 | 300-600kg/h |

| TSE-95B | 93mm | 32-64 | 600r/min | 250kw | 2387 | 800-1200kg/h |

2. Representative Materials

| Process | Representative materials |

| Mixing nature-changing | PE/ PP/ PS+SBS; PA+EPDM; PP+NBR; EVA +Silicon rubber, etc. |

| PE/ PA/ PC/ CPE+ABS(alloy); PBT+PET; PP+ PE, etc. | |

| Filling nature-changing | PE/ PP/ EVA, ect. + Calcium carbonate/ talcum powder/ titanic powder; ABS/PC/PS, etc. +aluminum hydroxide/ magnesium hydroxide/ antimony oxide. |

| PP/ PA/ ABS+ ferrous powder/ sulphuric powder/ ceramic powder | |

| Functional machine pellets | PP/ PA/ ABS/ PBT, etc+ anti-burning agent and other auxiliary agents: combustion-supporting machine pellets |

| PE/ PP/ PS, etc+ starch: de-composing machine pellets | |

| PE+ fog-preventing dipper, stabilizer: dual-prevention machine pellets | |

| PE/ EVA/ ABS, etc.+ carbon black; black machine pellets | |

| Colored machine pellets | PE/ PP/ ABS/ AS/ PA/ EVA/ PET +pigment and auxiliary |

| Intensified glass fibres and carbon fibres | PP/ PBT/ ABS/ AS/ PA/ PC/ POM/ PPS/ PET, etc. + long fires/ small fibres/ carbon fibres/ crystals and so on, etc. |

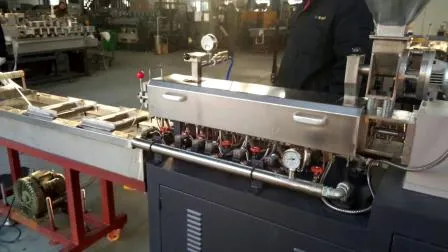

3. TSE Series Twin Screw Plastic Extruder Machine Product Display :

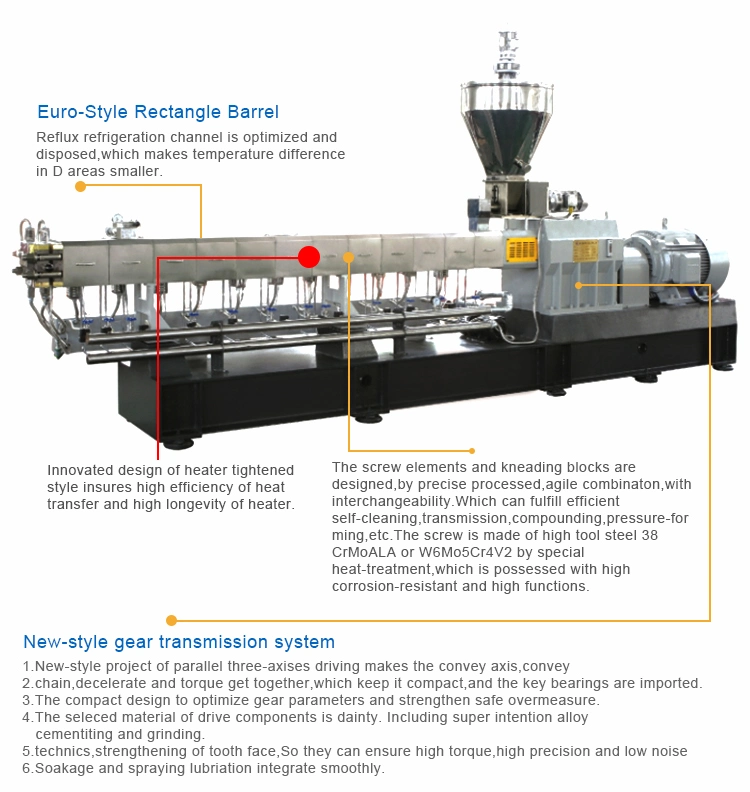

4. Characteristics and spare parts of the extrusion machine

1.The gearbox

· New-style project of parallel three-axises driving makes the convey axis, convey chain, decelerate and the torque assignment get together, which keep it compact, and the key bearings are imported.

· The select material of drive components is dainty, including super intension alloy cementiteing steel, cementiting and quenching, gear grinding technics, strengthening of tooth face. So they can ensure high torque, high precision and low noise.

· Soakage and coerce lubrication integrate smoothly. When the hydraulic circuit is over pressed, it alarms.

2.The feeding system

· Metering feeders are equipped with single screw, twin screw, hollow screw, forced-feeding, side feeding, liquid-adding system,etc.

3.Screw

· The screw elements and then kneading blocks are designed accurately, by precise processed, agile combination, with interchangeability, which can fulfill efficient self-cleaning, transmission, compounding, pressure-forming.

· The screw material is made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heat-treament.

4.The barrel

· Eurostyle rectangle barrel, reflux refrigeration is optimized and disposed, which makes temperature difference in C areas smaller.

· According to the material and special techinics demands, the material of cylinder can use high quality nitrided steel, corrosion proof or antifriction with corresponding process.

5.The heater

· Innovated design of heater tightened style insures high efficiency of heat transfer and high longervity of heater.

6.Pelletizing

· Variou modes of pelletizing, such as water-cooling strand, air-cooling pelletizing, water-ring pelletizing, under water pelleting, etc.

Work Line

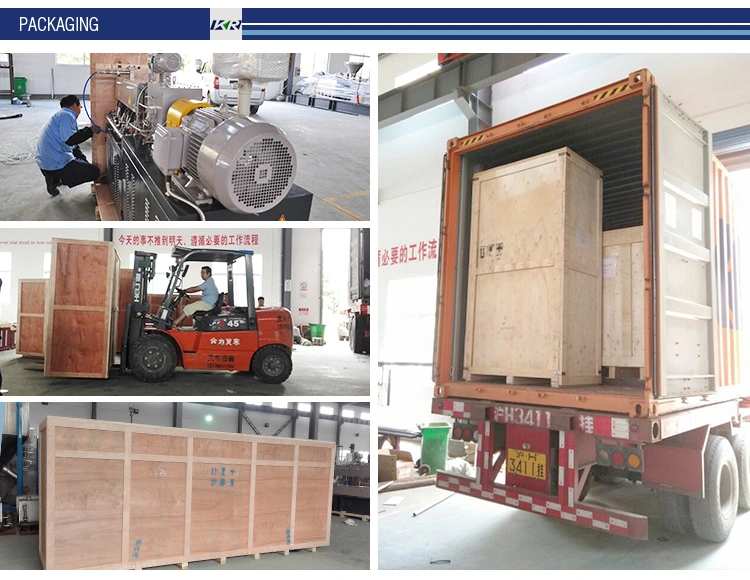

Packaging & Shipping

Our twin screw extruder machine is fisrt painted with anticorrosive oil, and then wrapped in the plastic film before it is finally packed in the wooden case.

1.

Q: How can we go to your factory?

R:Our factory is located in Nanjing jiangning, Jiangsu Province, China,

1) You can fly to Nanjing Airport directly. We will pick you up on Nanjing Lukou International airport; about 20 mintues to our company

2) You can fly to Shanghai Pudong International Airport then come to Nanjing by High-speed railway, then we will pick you up in the railway station.about 8 mintues to our company

All our clients, from domestic or abroad, are warmly welcome to visit us!

2.

Q: Why chose us?

R: 1)Quick reply. Once we received the inquiry from Alibaba, we will reply you within 24hours.

2)Quick manufacturing time. To guarantee the quality, the machine will be finished within 60days.

3) Before delivery, the machine will be tested to ensure every part is ok.

4) Wooden case package to ensure no damage during shipping.

3

Q:What is the payment?

R: 1) T/T payment; 2) LC;

Prev: Extrusion Pth-30 Co-Rotating Double Screw Plastic Compounding Lab Extruder

Next: Lab Twin Screw Extruder with Professional Configuration for Laboratory

Our Contact