Plastic Soft Rigid Net Extrusion Line\Filament Extrusion Equipment\3D Printer Filament Extrusion Line

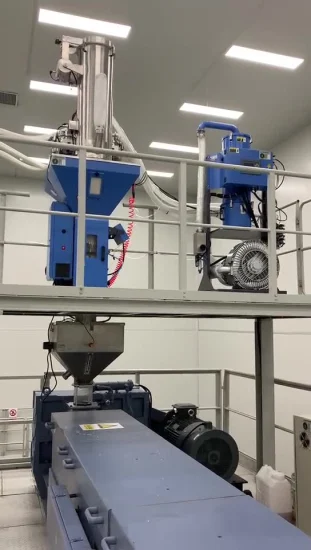

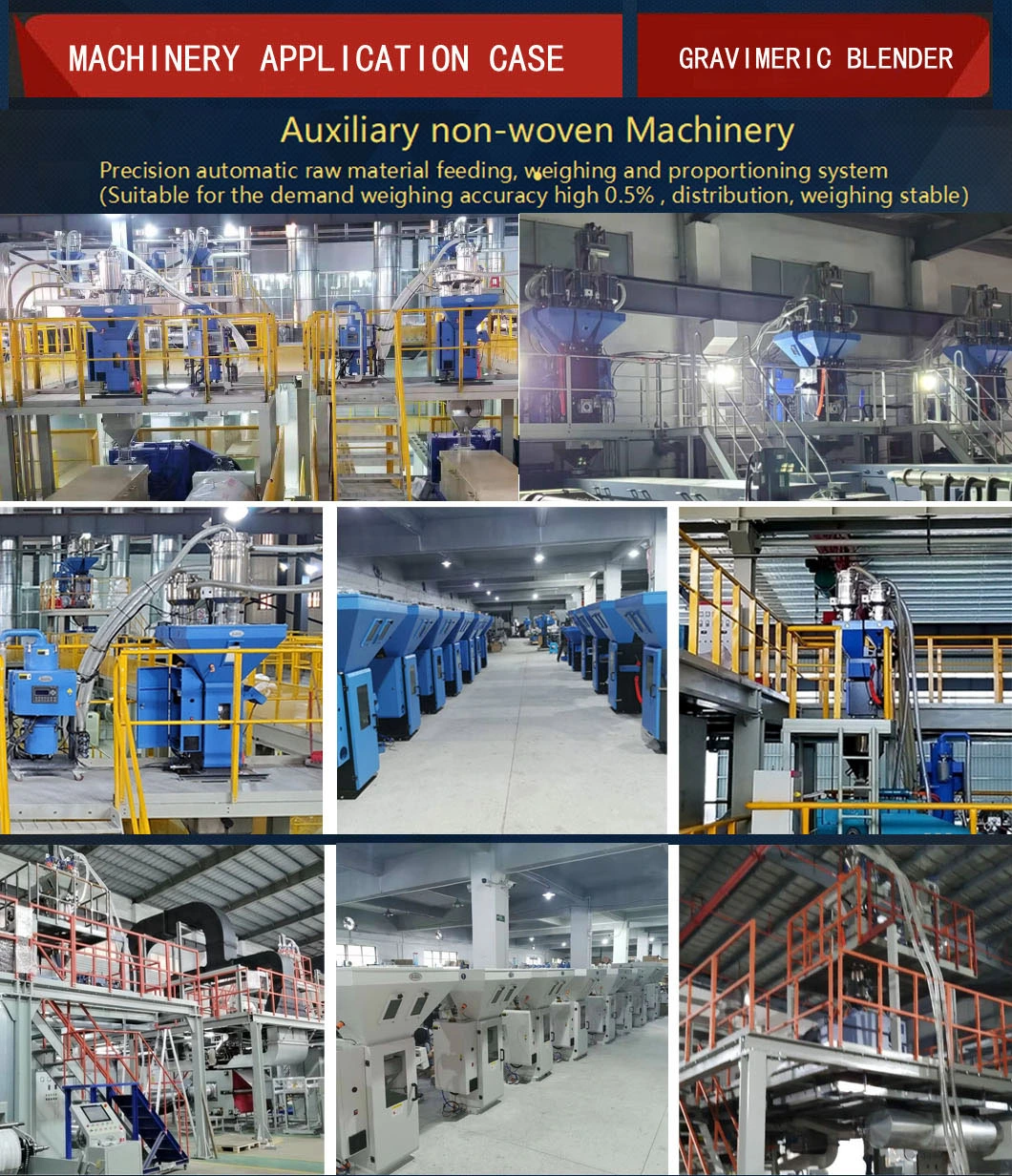

Scope of application: For the extruding online processes with multi, proportional and high precise of materials like pel

Description

Basic Info

| Model NO. | CGB-600-4 |

| Engagement System | Full Intermeshing |

| Screw Channel Structure | Non Deep Screw |

| Exhaust | Exhaust |

| Automation | Automatic |

| Computerized | Computerized |

| Capacity | 600kg/Hr |

| Usage | Mixer Equipment |

| Function | Automatic Operation |

| Power(W) | 0.55kw |

| Voltage | 3pH400V50Hz |

| Warranty | 1year |

| PLC | Siemens Brand |

| Weight | 180kg |

| Transport Package | Wood |

| Specification | 975*960*1675mm |

| Trademark | Sanzhong |

| Origin | Guangdong |

| HS Code | 84778000 |

| Production Capacity | 2000PC\Year |

Product Description

For the extruding online processes with multi, proportional and high precise of materials like pellets, sheets, regrinds or powder in plastics industry. Gravimetric dosing and blending unit for direct installation on the inlet flange of a plastics processing machine or on floor stand. The unit can dose and blend up to 4 components by standard and can be tailored for 6 components or more. Material blending with high accuracy and repeatability, specifically designed for injection moulding/blow moulding machines and extruders with an throughput from 50kg/h to 3000kg/hr. Actual metered and weighed amounts are constantly checked against the pre-selected set values by a modern PLC based control. This guarantees an exceptionally high recipe accuracy (±0.1~±0.3%) by continuous self-optimization.Dosing range: main component 5 - 100%, Dosing range: additive 0.5 - 10% - Power supply 1PH/230V 50HZ for CGB50 - CGB400, 3PH400V50HZ for CGB600 - CGB3000.

Feature:

| 1.Alll parts accessible for easy cleaning; |

| 2.Suitable for processing up to four components simultaneously; |

| 3.Built-in automatic loading control procedures; |

| 4.PLC controller, reliable performance, convenient maintenance; |

| 5.Adopting advanced control algorithm, autonomous optimization, automatic calibration and shaking prevent function, ensure the best accuracy; |

| 6.Color chart shown, touch screen operation, three languages on-line switching; |

| 7.Turbo control mode, improve production; |

| 8.Up to 100 recipes can be stored for later use; |

| 9.Multilevel password protection and historical alarm record; |

| 10.USB2.0 interface for saving recipe data to flash disk, Facilitate the Quality Management; |

| 11.With sound and light alarm, facilitate operator quickly and accurately reach fault machine area; |

| 12.All raw material contact parts are made by stainless steel, prevent the materials being polluted |

| 13.All raw contact parts are made by stainless steel, prevent the materials being pollute |

| Model | CGB-50 | CGB-100 | CGB-200 | CGB-400 | CGB-800 | CGB-1200 |

| H(mm) | 1010 | 1010 | 1225 | 1335 | 1875 | 1900 |

| W(mm) | 605 | 605 | 815 | 815 | 1060 | 1210 |

| D(mm) | 640 | 640 | 770 | 770 | 1070 | 1160 |

| Magnetic Base (mm) (H×W×D×W1×B×A×C) | 193×240×240× 180×140×13 | 193×240×240× 180×140×13 | 196×313×323× 180×150×13 | 196×313×323× 180×150×13 | 200×540×490× 220×180×13 | 200×540×490× 220×180×1 |

| Mobile Stand (mm) (H1×H2×W×D) | 700×750×680×530 | 700×750×680×530 | 800×850×780×610 | 800×850×780×610 | 800*70*1000*750 | 800*70*1000*750 |

| Net Weight (kg) (Machine Mount) | 90 | 90 | 130 | 140 | 200 | 250 |

| Net Weight(kg) (Floor Mount) | 110 | 110 | 155 | 165 | 250 | 340 |

Prev: Lab Mini 3D Filament Production Line Desktop for Laboratory Extrusion Machine

Next: 3D Filament Extruder/1.75mm ABS Filament Plastic Extrusion Machine Line for 3D Printing

Our Contact

Send now