Mini Lab Twin Screw Extruder for Plastic Compounding

Description

Basic Info

| Model NO. | TSH-35P |

| Assembly Structure | Separate Type Extruder |

| Screw | Twin-Screw |

| Engagement System | Intermeshing |

| Screw Channel Structure | Deep Screw |

| Exhaust | Exhaust |

| Automation | Automatic |

| Computerized | Computerized |

| Name | Plastic Twin Screw Extruder Machine |

| Motor | Siemens, Weg |

| Inverter | ABB, Toshiba, FUJI |

| Output | 15-65(According to Different Material) |

| Switches | France Schneider |

| Temperature Controller | Japan Omron |

| Certifications | CE, ISO, TUV, 30 Patents |

| Item | Plastic Twin Screw Extruder |

| Processing Material | PP, PE, ABS, PS, PA etc. Modification/Recycling |

| Motor Power | Decided by The Output You Need |

| Material Formula | Technical Instruments |

| Overseas Service | Provide |

| Transport Package | Wooden Box, Bubble Film, Wrapping Film |

| Specification | 18.5kW |

| Trademark | TENGDA |

| Origin | Jiangsu, China |

| HS Code | 8477209000 |

| Production Capacity | 10 Piece/Pieces Per Month |

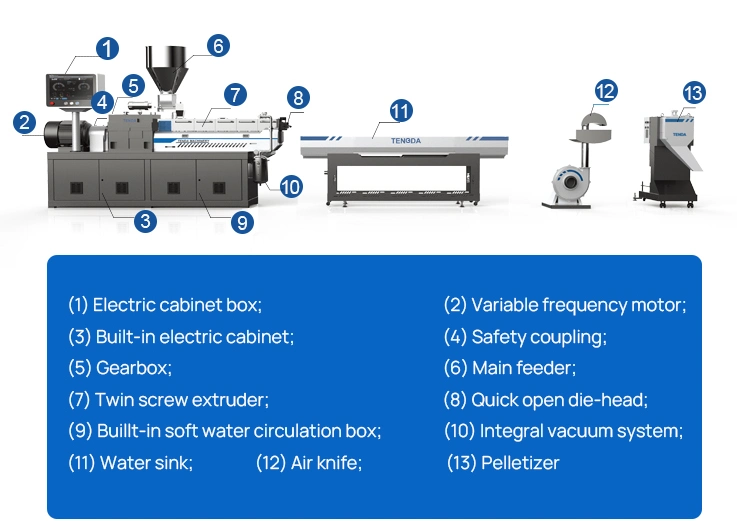

Product Description

mini lab twin screw extruder for plastic compounding

Product model for your choosing:(Notes: Different raw materials, the output is different, please tell me what's the material you want to produce, I will recommend you the correct model.)| Type | TSH-20 | TSH-35 | TSH40 | TSH52 | TSH65 | TSH75 | TSH95 |

| Screw Diameter (mm) | 22 | 35.6 | 41 | 51.4 | 62.4 | 71 | 93 |

| Screw Speed (rpm) | 600 | 600 | 600 | 600 | 600 | 600 | 600 |

| Motor Power (kW) | 4 | 18.5 | 30 | 55 | 90 | 132 | 315 |

| L/D | 32-60 | 32-68 | 32-68 | 32-68 | 32-68 | 32-68 | 32-68 |

| Output (Kg/h) | 2-15 | 15-95 | 70-120 | 155-255 | 255-400 | 450-750 | 950-1600 |

| Type | TDH-35 | TDH40 | TDH52 | TDH65 | TDH75 | TDH95 |

| Screw Diameter (mm) | 35.6 | 41 | 51.4 | 62.4 | 71 | 93 |

| Screw Speed (rpm) | 600 | 600 | 600 | 600 | 600 | 600 |

| Motor Power (kw) | 30 | 45 | 75 | 132 | 250 | 550 |

| L/D | 32-68 | 32-68 | 32-68 | 32-68 | 32-68 | 32-68 |

| Output (Kg/Hr) | 10-150 | 100-230 | 200-380 | 400-660 | 750-1250 | 1650-2750 |

Product details:1. Twin screw main extruder: Main motor: Imported "WEG"or "SIEMENS" Variable frequency motor(The frequency converter will automatically change the frequency to reduce the frequency of the motor. The operating current will always run between 80%, 50%, and 30% of the rated power. This will greatly reduce the motor's operating current and achieve the effect of saving electricity).

2. Gearbox: Warranty: 3 years; (2)Concentricity deviation of output shaft and input shaft: within 0.2mm; (3)Both output shaft radial bearings are imported "IKO"and "NSK" bearings;3. Electric cabinet box: (1)Inverter: Imported Switzerland"ABB", Japan"TOSHIBA","FUJI"; (2)PLC: Imported "SIEMENS" brand; (3)Main electrical controller:"Schneider" brand; (4)Display of electric current:Japan "OMRON" brand; (5)Temperature instruments: Japan "OMRON" brand;

4. Twin-screw BarrelBimetal wear-resistant and corrosion-resistant material, the base material is 45# steel, after multiple forging, quenching and tempering treatment; the cylinder is inlaid with α-101 wear-resistant and corrosion-resistant alloy bushing, which has better wear resistance and corrosion resistance than general alloy bushings.

5. Screw elements(1)Material is W6Mo5Cr4V2 (high speed tool steel) with the best wear resistance, the whole adopts vacuum quenching treatment, hardness is 60 ~ 62HRC; (2)Designed by the building block principle, and the screw element and the screw shaft are connected by an involute spline, and the screw combination can be adjusted according to the process requirements; The screw elements are all made by CNC machining center, with good identity and strong process repeat-ability,which is benefit for changing;6. Screen changer+Die-head: Quick open die-head, convenient and fast, short flow path of the machine head and less material storage can significantly reduce the deterioration of the material's physical properties, yellowing, black spots and other defects;

Machine applications:

(1) Biodegradable material: PE/PLA/PBAT+starch/additives etc.;(2) Thick masterbatch:PE, ABS, PS, PP+ pigment, additives;(3) Flame retardant masterbatch: PP, PA, ABS+ flame retardant, additives, etc.;(4) Filling modification: PE/EVA+ calcium carbonate, talc powder,TiO2,carbon black, etc.;(5) Enhanced modification:PP,PA,PBT, ABS, AS, PC, POM, PET +glass fiber, carbon fiber;(6) Blending alloy: PC+ABS, PA+ABS, CPE+ABS, PP+EPDM, PA+EPDM, PP+SBS etc.;(7) Cable material: PVC,PE,low smoke and halogen free etc.;(8) Engineering plastics: ABS,PEEK,PC etc.;(9) Thermoplastic elastomer:TPU,TPE etc.;(10) Color masterbatch: PE, ABS, PS, EVA, PET, PP+pigment, auxiliaries;(11) Flame retardant color mother: PP, PA, ABS, EVA, PBT+flame retardant.

Company Profile:

Exported to 60+countries, 10000M3 Factory area, 13 years history.

Tengda twin-screw extruder-a pioneer in the development of twin-screw extruders, specializing in the design of various plastics(PP PE ABS PC TPE etc.), environmentally friendly materials (biodegradable resins), water-soluble materials, chemical, etc.compounding systems manufacture. In order to promote the research and development of high-end twin-screw, we established a twin-screw business research and development department with China North Industries Group in 2013. Our company has passed ISO,TUV, CE certification, and has 17 utility model patents, 4 invention patents, and 1 appearance patent.Tengda twin-screw extruder has a lot of experience and exclusive technology. Cooperating with us, you can obtain the best solution for every compounding requirement, from laboratory-level special applications to industrial production. The teams of Tengda's various divisions composed of engineers, chemical researchers, technicians and experts in various fields will provide customers with powerful process solutions.Tengda twin-screw extruder adheres to the tenet of paying great attention to the customer's use of the equipment, focusing on the high production and efficiency of the equipment, the orderly design and the purpose of serving customers, to design and deliver the ideal equipment, and continue to create more value for customers.Enterprise Mission: Let every user of our machine use the peace of mind, rest assured, worries, create a win-win model, and continue to develop for at least 192 years,three centuries, the same dream!Enterprise Version: Constantly surpass, committed to become an internationally competitive national enterprise. Let the plastic granules produced by Tengda Machinery extensively applied in every corner of the world, let Tengda become a production source that is indispensable for people's life;Business philosophy: Quality-oriented, Remain true to our original aspiration and keep our mission firmly in mind.

Our certificates:Our company was awarded as Jiangsu High-tech Enterprise and National High-tech Enterprise.Won the title of"2021 Nanjing Gazelle Enterprise". This award represents the recognition by the Municipal Development and Reform Commission of Nanjing Tengda's prosperous and healthy development over the years and its achievements.Our company has passed ISO:9001 international quality management system certification,EU CE certification, TUV Rheinland certification, and has more than 30 patents.

Our customers:

Related products:https://chinatengda.en.made-in-china.com/product-list-1.htmlFAQ:

Q: Are you trading company or manufacturer?

A: We are factory.We have the technical production team,and the workers are all very experienced

Q: Why choose you?

A:You can get a very fair price from us and our price can make you beat your competitors in the markeQ: What kind of certification do you have?

A: Our products have obtained ISO9001 and CE certification,the quality can be guaranteed.We focus onthe field of extrusion machine,and aim to be the best manufacturer of this field

Q:What's the payment?

A:L/C, T/T, Western Union, Paypal, Money Gram, Cash.

Prev: Small Lab Twin Screw Plastic Compounding Extruder 10% off

Next: Laboratory Miniature Rubber Material Extruder of Extrusion Torque Rheometer

Our Contact