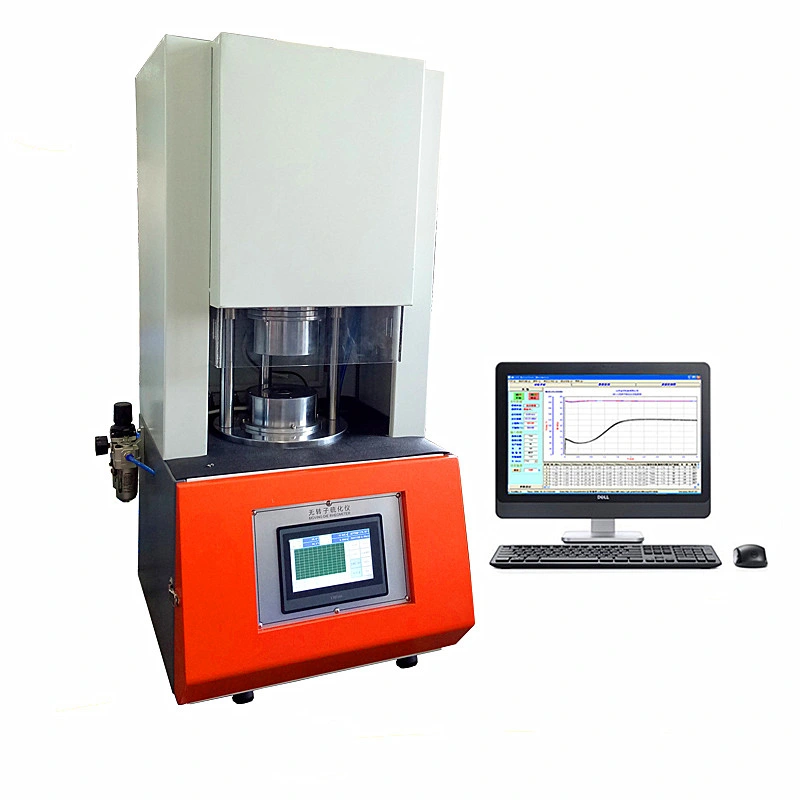

Alpha Automatic Flat Disk Rubber Moving Die Rheometer

Description

Basic Info

| Model NO. | YK-2018 |

| Loading Method | Dynamic Load |

| Display | Digital |

| Control | Computer Control |

| Weight | 100-500Kg |

| Power Source | AC220V |

| Oil Cylinder Position | Under |

| Load Cell | United States High-Precision |

| Bearing | Japan NSK High-Precision Bear |

| Control Mode | Computer Temperature Control |

| Fixtures | Sino-Foreign Joint Venture Germany West Pneumatic |

| Report Content | Ml, Mh, Ts1, Ts2, T10, T30, T50 |

| 70, T90, Vulcanization Curve Standard | ASTM D5289-95, ISO 6502 |

| Transport Package | Standard Exported Wooden Case |

| Specification | Electronic |

| Trademark | Evertech |

| Origin | Qingdao, China |

| HS Code | 84778000 |

| Production Capacity | 999 Set/Sets Per Year |

Product Description

Quick Details

Place of Origin:Hubei, China (Mainland) Brand Name:Bonnin Instrument Model Number:BN-4000B

Power:Electronic Usage:rubber testing equipment Equipment name:Automatic Disk Moving Die Rheometer

Load cell:United States high-precision sensors, 0.001N.M Bearing:Japan NSK high-precision bearings

Control mode:Computer temperature control, Alpha technology accuracy of 0.01 ºC

Fixtures:Sino-foreign joint venture Germany West pneumatic components

Report content:ML, MH, ts1, ts2, t10, t30, t50, t70, t90, vulcanization curve

Standard:ASTM D5289-95, ISO 6502

Rubber disk moving die rheometer, also named of Alpha movind die rheometer, used for the analysis and determination of rubber vulcanization process, such as scorch time, positive curing time, curing rate, viscoelastic modulus and vulcanization flat period and other performance indicators. This rubber rotorless rheometer is a testing equipement for testing the quality of rubber products and the development of new products

BN-4000B Automatic Disk Rubber MDR Moving Die Rheometer

Main features:

1. The instrument uses a real closed cavity, and the United States Alpha (the original Monsanto) same. Repeatability and test data are comparable to alpha. In the international industry in the leading position.

2. The instrument based on large-scale database development platform, temperature control device using software direct control and acquisition and processing. This technology leads the international trend.

3. The instrument has statistics, analysis, storage, comparison and other functions. User-friendly design, easy to operate.

BN-4000B Automatic Disk Rubber MDR Moving Die Rheometer

Main configuration:

1. Real high-precision closed cavity structure with the United States Alpha synchronization.

2. United States high-precision sensors, precision of 0.001N.M

3. Japan NSK high-precision bearings.

4. Sino-British joint venture SDPC Group high-performance cylinder.

5. Sino-foreign joint venture Germany West pneumatic components.

6. Powerful dedicated module, advanced technology, test data and alpha synchronization.

7. The door automatically lift, security protection.

8. The key components of electronic components using military components, reliable quality, stable performance.

9. Computer software directly temperature control, Alpha technology accuracy of 0.01 ºC.

10. 19 inch brand LCD computer, HP color printer.

BN-4000B Automatic Disk Rubber MDR Moving Die Rheometer

Main technical specifications:

Temperature range: 0 ~ 200 ºC

Heating time: ≤ 10min

Mold body temperature fluctuation: ≤ ± 0.1 ºC%

Torque range: 0 ~ 20N.m

Swing frequency: 1.7Hz (100r.min-1)

Swing amplitude: ± 0.5 ° ± 1 °

Mold cavity structure: Monsanto form

Report contents: ML, MH, ts1, ts2, t10, t30, t50, t70, t90, vulcanization curve, temperature curve

Standard: ASTM D5289-95 ISO 6502: 1991 GB / T16584-199

Power supply voltage: AC220V ± 10%

Dimensions: (L*W*H) 680mm * 650mm * 1100mm

Net weight 230Kg

Packaging & Delivery

Packaging Details

Inner packaging with PE protective film, and outer packaging with standard export wooden box.

Delivery Time

7 working days after order confirmed

Detailed Images

Our Service

1.After-service:

If you face any problems in future during testing process we promise we will give you a reply within 48 hours and solution provide within 3 working days. We can offer operation video and English operation manual. We can provide video-con.

2. Middle service

-Give you best offer-Provide discount for many sets order--Do customer's request:--Choose payment term you convienent.

Promptly production and delivery,inform you in time.--Can provide invoice value as you like to decrease your tax.

3. After sale service

--1 year warranty service and all life maintenance.--Technical Egineer are avalible for oversea trainning.--Free change for some parts--Remote control technical consult--Free installation DVD--Maintenance plan

Packing & Delivery

FAQ

Skype | evertechvictor | ||

+8615269210610 | |||

| 1903209351 | |||

TEL | +86 15563910004 | ||

web | evertech.en.made-in-china.com | ||

Address | No. 66, Renmin Dong Road, Huangdao District, Qingdao |

Prev: Bituminous Mixtures Bending Beam Rheometer

Next: TPU/PET/PE/PP Lab Plastic Cast Film Machine Casting Film Mini Extruder Machine Film Making Machine

Our Contact