800mm - 2000mm Computerized Coating Extrusion Laminating Machinery

Description

Basic Info

| Model NO. | SJLM800-2000 |

| Membrane Material | Light Membrane |

| Plastic Film Mulching Modes | Hot Laminating |

| Performance | Waterproof |

| Material Feeder | Automatic Vacuum Loading |

| Screw Material | 38crmoaia Nitrogen Treatment |

| L:D | 35:1 |

| Driving Speed | Frequency Adjustment |

| Extrusion Die | T Die Like Clothes-Rack |

| Film Forming | Casting |

| Cooling | Internal Circulation |

| Cutter | Pneumatic Cutter Online |

| Edge Recycling Assistant | Trimming Recycling |

| Transport Package | Container |

| Specification | Extrusion single or double sides |

| Trademark | PASO |

| Origin | China |

| Production Capacity | 180 Sets Per Year |

Product Description

Usage:

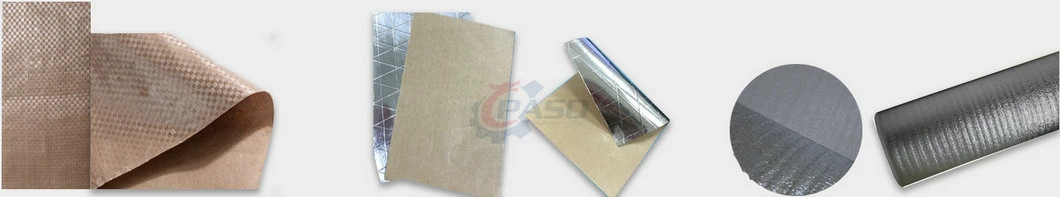

Extruding flow membrane & cartoons(brown packing paper, paper for cup, good quality paper),clothing metal foil, plastic bags as well as other synthetical material.

MAIN FEATURES:

SJLM-800-2000 Serial healthy environmental shower membrane machine and paper plastic composition unit(non-adhesive composition unit)which integrare winding, drying,surface process, composition, edge-cutting,adsorption dege with rewinding ate adopted with photo-electricityt tracking,electric-flower process; linespeed length of material digital display;full autmatic etemal tension,temperature-automatic control etc advance technologies;

It is suitable for extruded plastic cast film (PE, TPU, EVA, TPE, etc.) and OPP film, PET film, aluminum film and other materials single-layer coating or coating compounding.

Scope of application: can be used for paper-plastic composite, plastic composite, aluminum-plastic composite, aluminum-plastic composite, etc., widely used in plastic film, food packaging pharmaceutical packaging, shoe materials, luggage materials and other industries and fields,

Product features

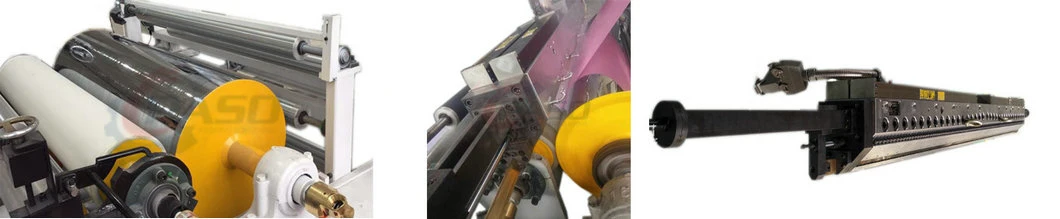

1. High-precision T-shaped touching head, finishing to ensure the uniformity of coating.

2. High-speed and high-efficiency mixing screw (German technology), according to the raw material attributes used by customers, design screw structure, can be equipped with static mixer and fluid pump, etc.

3. Independent design of pneumatic quick screen change, simple operation without material leakage, 360 degree second unwinding frame

4. The whole machine can adopt monotonous or PLC man-machine interface centralized control, mechanical and electrical integration design

5. The whole machine can be individually designed according to the different requirements of customers, with glued parts or baking channels or with printing, which can fully meet the different needs of customers.

6. It can be equipped with single extruder, double extruder, and multiple extruders to achieve multi-layer co-extrusion

| ITEM/TYPE | SJLM-800 | SJLM-1000 | SJLM-1200 | SJLM-1600 | SJLM-1800 |

| Length of mold lip | 900mm | 1100mm | 1300mm | 1700mm | 1900mm |

| Width of finished product | 400-800mm | 500-1000mm | 600-1200mm | 800-1600mm | 900-1800mm |

| Max compounding speed | 80-150m/min | 80-150m/min | 80-150m/min | 80-150m/min | 80-150m/min |

| Width kf shower film | 0.01-0.1mm | 0.01-0.1mm | 0.01-0.1mm | 0.01-0.1mm | 0.01-0.1mm |

| L/D ratio for screw | 35:1 | 35:1 | 35:1 | 35:1 | 35:1 |

| Max. diameter for roll unwinding and rewinding | ø1300mm | ø1300mm | ø1300mm | ø1300mm | ø1300mm |

| Overall size | 12000×6000×3200mm | 12500×7000×3200mm | 1300×8000×3200mm | 12000×9000×3200mm | 13000×12000×3200mm |

| Power | 60kw | 70kw | 80kw | 100kw | 130kw |

| Compounding/mirror cool roll | ø510mm | ø510mm | ø510mm | ø510mm | ø510mm |

| Applicable for base material | BOPP BOPPET BOPA CPP CPE PAPER MPET VMPET | ||||

1.Packaging: wooden pallet or film wrapped (Fumigation wooden case usually)

2.Delivery time: 5-35/55 days after receiving deposit, depends on order and machine condition.

3.Exporting seaport: Ningbo port ; Shanghai port

4.Payment: we appreciate T/T 30% deposit, 70% balance paid before dispatching; Western Union;L/C acceptable if your goverment policy required

5.Trade terms: ExW,FOB,CFR,CIF,Door to Door, DDU, DDP,

1.Where is your factory Located

Our Factory Located in Ruian City ,Zhejiang Province ,China .

It is about 30minutes by air from Shanghai, around 5hours by train from Shanghai

2.What machines range we make & supply?

Our factory focus on manufacturing extrusion lines, complete bag production line, etc; OEM, ODM, with support of strong R&D team, we also help customer get best solutions for special equipments and plastic machinery;

3.How can we get satisfied machine in hand?

We will make test once machine in ready, to check every parts working condition and electrocircuit; will record relative photo and video for installation in your place.

3. What should we charge if we need engineer service in our country?

You should charge for the cost of our engineer's visa, air tickets, hotel, food, and also their salary (negotiable)

4. How long is your machine's warranty period?

All our machine have two years guarantee, starting from finished installation. we still keep service for whole life.

5. How could we do if the parts broken within warranty?

We would send the free replacement spare parts during the warranty date.

Prev: Laboratory Thermoplastic Polymer Film Casting Machine

Next: Packing Machine Paper and Aluminum Foil Extrusion Coating Laminating Machinery Hdlm90-1600

Our Contact